MITUTOYO - CNC Coordinate Measuring Machine : CRYSTA-Apex V Series| JSR GROUP

CNC Coordinate Measuring Machine CRYSTA-Apex V Series

CRYSTA-Apex VSERIES

Introducing generation CNC coordinate measuring machine focused on accuracy, speed, and versatility.

We are proud to unveil our CRYSTA-Apex V Series that delivers faster measurement of small- to large sized parts without compromising the measuring machine’s inherent accuracy, and helps make the smart factory a reality.

A brand CMM design that provides cutting-edge capability in an extensive series of models that covers practically any measurement application in the small- to large sized part range.

The aesthetic design sports bold colours that befits a precision measuring instrument of the IoT age.Offering a choice of models for measuring from small to large sized workpieces, the CRYSTA-Apex V Series delivers advances in accuracy, speed and versatility in this class of CMM.

HIGH PRECISION

|

Absolute quality Provides a performance specification unmatched by any previous CMM of this class through features that include an advanced real-time thermal compensation system which makes measurement accuracy practically independent of temperature changes in the environment. This is in stark contrast to earlier generation CMMs where accuracy could not be guaranteed unless the machine was installed in the controlled environment of a measuring room held as closely as possible at the standard temperature of 20 °C |

|

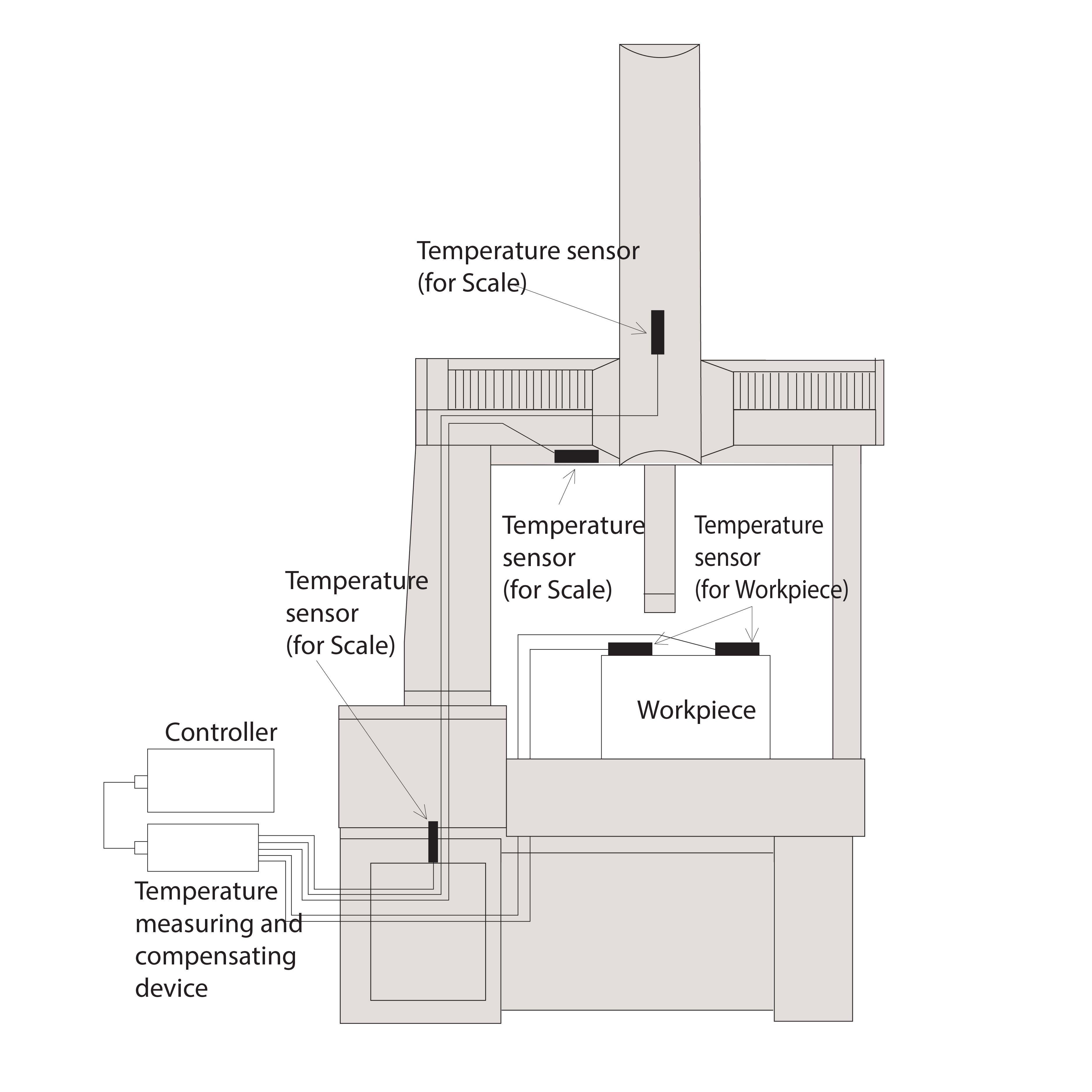

Real-time temperature compensation

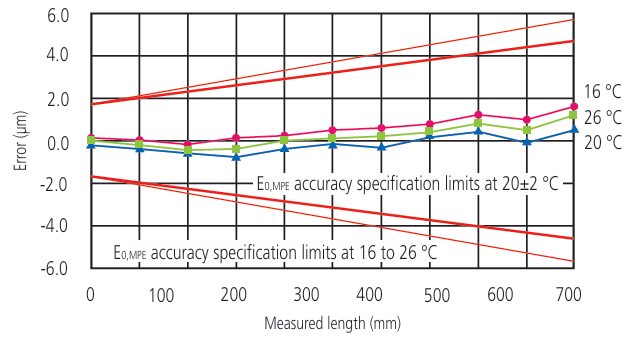

Mitutoyo’s thermal compensation system technology enables the CRYSTA-Apex V Series to maintain specified accuracy over the wide temperature range of 16-26 °C. The system operates by continuously tracking the temperature of the workpiece and every scale on the CMM and using this data to calculate and apply corrections to themeasurement output. Thus the CMM appears to be performing as if it is always operating at a constant temperature of precisely 20 °C.

Graph showing the effectiveness of temperature compensation |

High accuracy in the 1.7 μm class

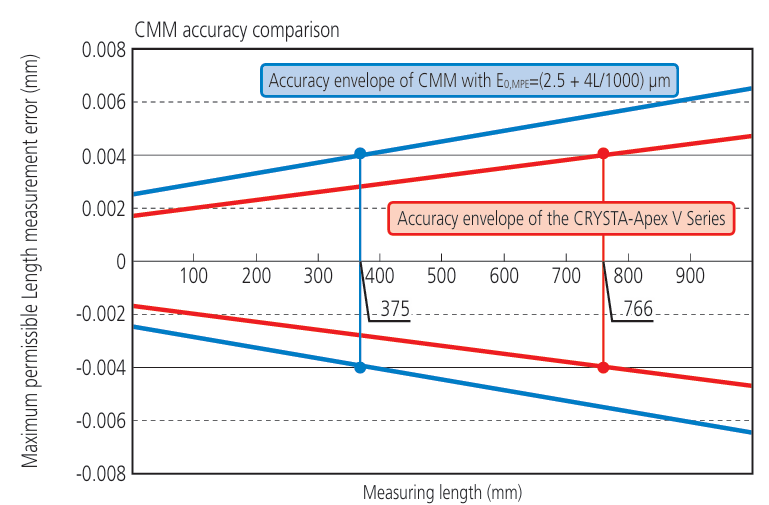

* Assuming an acceptable working ratio between component tolerance and accuracy of measurement is 5:1 minimum. The CRYSTA-Apex V Series guarantees a maximum permissible length measurement error (E0,MPE) of 1.7 + 3L/1000 μm, a specification that compares very favourably with a standard CMM offering an E0,MPE of 2.5 + 4L/1000 μm, which would generally be considered high accuracy. To illustrate the practical advantage of the higher specification of the CRYSTA-Apex V Series, consider the case where the tolerance on a dimension is ±0.02 mm: the measurement uncertainty of the standard machine exceeds one-fifth of this tolerance* for any length over 375 mm. In contrast, the V Series uncertainty remains within one-fifth of the tolerance for measured lengths up to 766 mm. Hence the V Series actually offers guaranteed accuracy over more than double the measuring range of the less accurate standard machine. |

|

Repeatability Excellent measurement repeatability is essential for high accuracy and this is especially true when using scanning probes to measure complex 3D surfaces, an application where dynamic errors can occur if precautions are not taken. In this scenario the data from the scanning probe is stabilised by holding the probe stationary for a short time whenever the stylus tip contacts the workpiece, thereby ensuring that inertial causes of dynamic error are eliminated, making it possible to deliver the best possible level of repeatability obtainable from the CRYSTA-Apex V Series machines. |

HIGH SPEED

|

Dramatically reduces measure ment time with high-speed measurements The V Series enables users to freely set measurement paths along three-dimensional surfaces, enabling complex workpieces to be measured most efficiently. High-speed measurement is unaffected by processing accuracy through real-time correction of path errors caused by differences between workpiece and design values. The V Series, with its high drive speed and acceleration combined with a maximum measuring speed of 8 mm/s, dramatically reduces total measuring time. |

|

Speed and acceleration to reduce measurement time

The CRYSTA-Apex V Series offers a maximum drive speed of 519 mm/s and a maximum acceleration of 2,309 mm/s2. Compared with conventional CNC CMMs (typically around 430 mm/s and 1,650 mm/s2), this amounts to about 100 mm more traverse distance one second after starting movement. This faster movement capability, combined with a maximum measuring speed (the speed with which the stylus traces over the workpiece) of 8 mm/s, much faster than conventional CNC CMMs (typically around 5 mm/s), cuts total measuring time significantly. The more the number of measurement locations, the greater this margin grows, which in turn results in significant cost savings |

|

High-speed optimum path scanning

The V Series is equipped with a measurement feature that allows users to specify scanning measurement paths (design values). This feature allows for high speed, high-accuracy scanning by correcting dynamic errors that would otherwise be produced by acceleration and deceleration stresses. Measurement paths can be freely specified for three-dimensional forms as well, which enables intricate workpieces to be measured |

Active scanning feature

Enables high-speed measurement by accommodating discrepancies between design values and the actual workpiece. The 3D optimal path scanning advantages are retained whilst allowing for manufacturing or alignment deviations. The complexity of some workpieces. (e.g. turbine blades, fan blades and impellers)

|

DIVERSITY

|

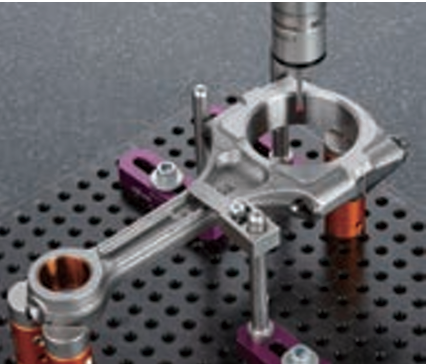

Efficient, high-accuracy measurement of practically any part shape The CRYSTA-Apex V Series is suitable for a wide range of applications using touch-trigger, scanning and non-contact probes in fully automatic part-program measurement cycles. |

Probes for Coordinate Measuring Machines

|

5-axis Control touch-trigger probe system PH20 The PH20 head can position a touch-trigger probe at any angle, allowing unique "head touch" probing. This system has the advantage of measuring tilted surfaces and small, deep holes. There is no fear of interference from the stylus shank during measurement of a deep hole.5-axis operation reduces the time required for probe rotational movements and supports "head

|

|

|

Compact high-accuracy scanning probe SP25M The SP25M is a compact, high-accuracy scanning probe with a 25-mm outside diameter. It is a multi-function CNC CMM probe that can collect data not only from scanning measurements, where the probe moves while in contact with the workpiece to collect a point-cloud of coordinate values, but from high-accuracy single-point measurements as well.

|

|

|

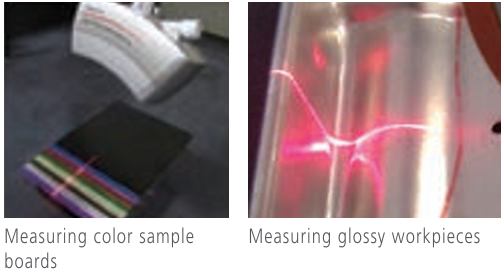

Non-contact laser probe SurfaceMeasure SurfaceMeasure is a non-contact probe that collects coordinate values of the surface of a workpiece by using laser light. It can quickly obtain a point-cloud of 3D surface data.

|

|

Efficient, high-accuracy measurement in a variety of applications

The CRYSTA-Apex V Series is suitable for a wide range of applications using touch-trigger, scanning and non-contact probes in fully automatic part-program measurement cycles

|

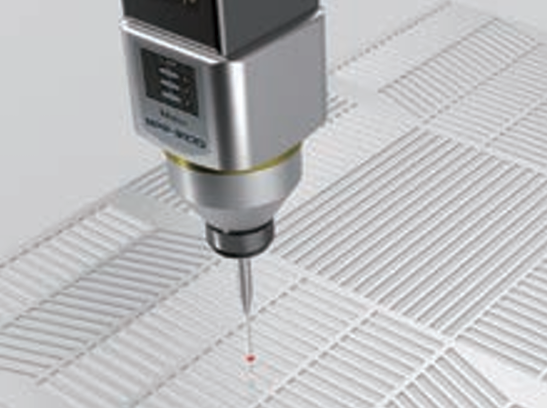

Electric-cell separator moulds

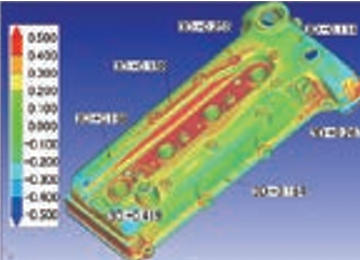

Surface and cross-section measurements on precision moulds for the separators used in electric cells can be made using a low measuring force, high-accuracy scanning probe. Three-dimensional error and cross-sectional form analyses may be performed using the measurement data obtained

|

Pump impellers

Complex shapes such as pump impellers can be measured using a robust non-contact laser probe that produces huge amounts of data in the form of a point cloud to provide highly detailed measurement data for excellent characterisation of the part.

|

|

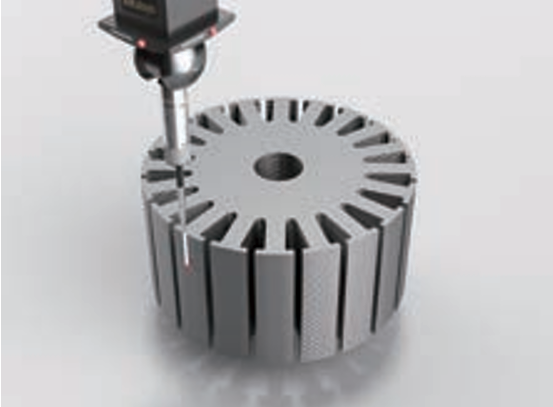

Electric motor core

Surface and cross-section measurements on precision moulds for the separators used in electric cells can be made using a low measuring force, high-accuracy scanning probe. Three-dimensional error and cross-sectional form analyses may be performed using the measurement data obtained. |

Turbine and fan blades

The cross-section of aircraft engine aerofoil components can be measured using a compact, high-accuracy scanning probe. Even workpieces susceptible to large errors, such as castings, can be measured quickly and reliably. |

|

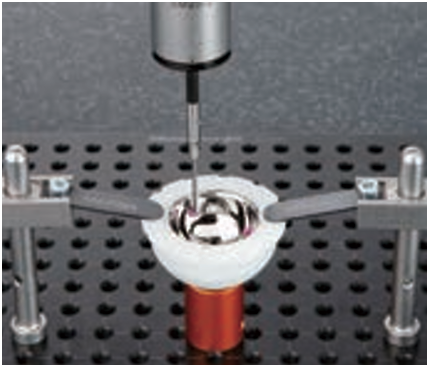

Artificial joints

Freeform surface measurement of artificial joints can be made using a compact, high-accuracy scanning probe. Three-dimensional error analysis can be performed using the measurement data obtained |

Transmission cases

Non-contact laser probes require dramatically less measurement time compared to contact (scanning) probes. Scanning from three directions enables simultaneous measurement of the top and side faces, which means less repositioning and efficient measurement of even the most intricate parts |

SOFTWARE

|

Application software that offers functionality and ease of use Mitutoyo offers an extensive choice of application software for automatically generating part programs to perform measurement and evaluation of simple or complex components, including gears and aerofoils. Practically any measurement challenges that our customers may encounter can be tackled by V Series machines. |

|

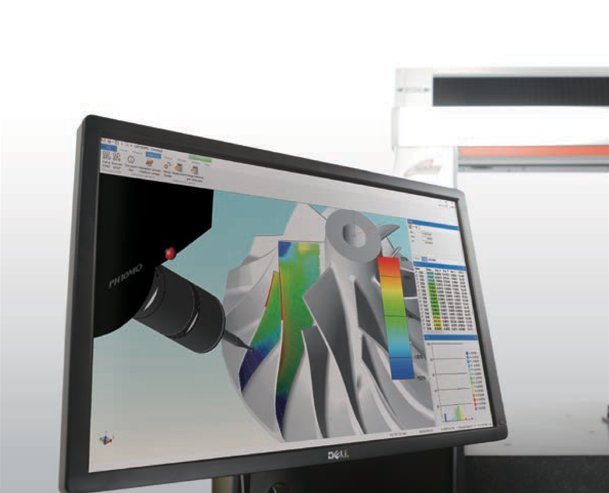

MCOSMOS MCOSMOS is Mitutoyo’s suite of PC-based CMM software applications that consists of optional modules to support fully automated measurement of all kinds.

|

MiCAT Planner This software package dramatically reduces part-programming creation time by automatically generating the part program. Tolerance information from a 3D CAD model is read to determine which features of the part should be measured to verify conformance to specification. Compared to conventional methods (teaching), this method creates more-efficient measurement programs as well as saving time.

|

|

MSURF The MSURF software package comprises MSURF-S for scanning measurement of a part and MSURF-I for comparing the resulting measurement data against the master model data.

|

|